At Nike, Cedric brought the process of collecting data from an eight-hour process to an automated, weekend-run process that required only seconds to review on Monday morning. Instead of showing up on Monday and running Teradata queries during peak time, Cedric used an Alteryx Daemon to pick up the data on Sunday nights while all were asleep. The driver then emailed a status report; if he was not, he sent a copy of his diary, tried a second time from where he failed, and then sent a second copy of his diary. Every Monday, Cedric was able to read this diary, retrace those steps, and in the rare times he was unsuccessful, finish his tasks.

Using Tableau, we were able to get a picture of the health of our inventories and our process. This story was presented this to our internal staff (three with a doctorate, of course, as you have in any lab) as well as to our stakeholders, who were also the stewards of of our data. This process prevented stock-outs for over 3000 products in three geographies.

Safety Stock is a critical tool for Nike’s on-demand business line. Is it something you need to investigate further?

Data Quality: From 2021-2025, Cedric served Nike as an independent consultant for Nike’s Consumer Creation division, governing the entire portfolio’s data quality. The data engineering role was to automate data-quality audits using Alteryx and to provide data modeling resources. Transitioning from one data set to another, updating databases, and updating architecture require the most modern and best data modeling techniques; this role was to provide that feedback and modeling so that the data is as clean, functional, and intuitive as possible. It’s not 1999, we don’t need fieldnames like X_COV_GLT any longer. And TRUE and FALSE fields should be boolean, not text.

Data Maturity

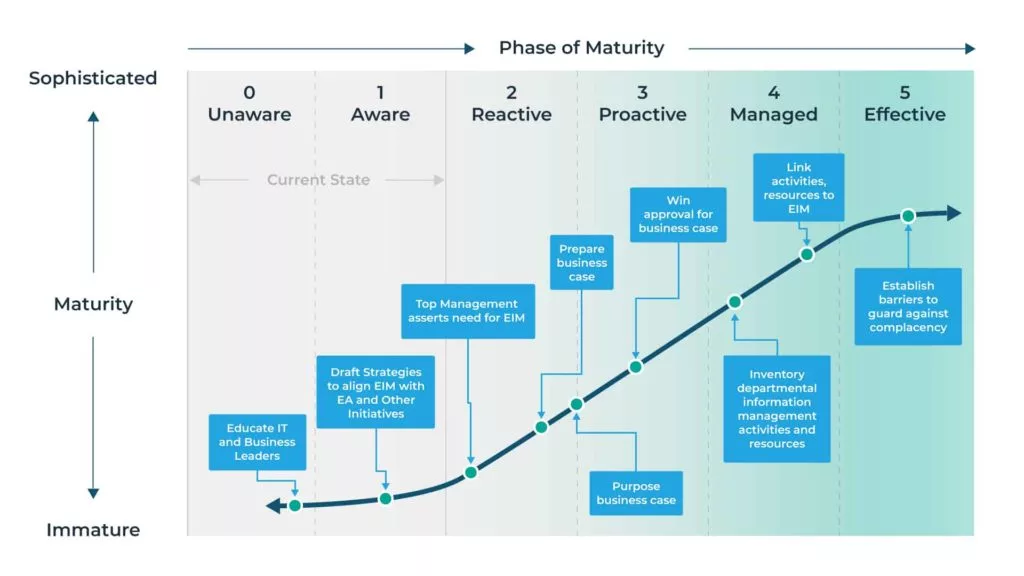

Not every company uses data as an asset. There is a data maturity model at play. Where Colourless Green sits best is with those lower-maturity companies that still have challenges with integration of data across business units. This was why consulting work was valuable and why Colourless Green was an asset at Nike. Despite its size, Nike was not a mature user of data in the contexts we were exposed to.

Leadership and management affect data and operations. Data is not independent of business process, but rather a policy of it; making changes required change management, engagement, and decision-makers to make sure these processes were not just audits, but rather, embedded into systems. That was outside of the scope of this role, but it was obvious within the role that this complexity exists. It made Colourless Green more excited to assist companies with their data challenges, even as an interim step, while developing more holistic solutions.

This isn’t the sort of stuff AI is going to get you moving forward on. It can help with coding, but with organisational change, we’re not there yet. And without a good quality of data or a system in place, data processing cannot be abstracted well enough to be useful to AI. You need to have a dialled-in process in order to capitalise on AI.